Ford pilots 3D Printing for prototyping components and future vehicles

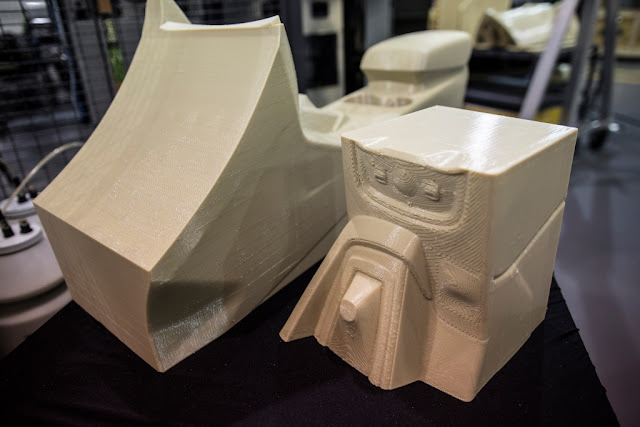

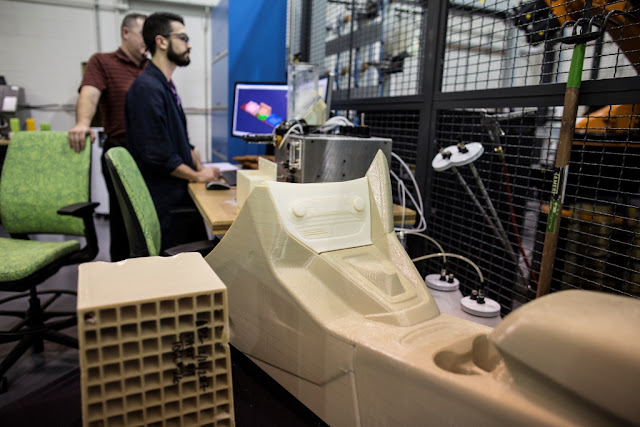

Capable of printing car parts of practically any shape or length, the Stratasys Infinite Build system provides an efficient and affordable way to produce vehicles, making design iterations a lot easier.

Companies world over are now employing 3D print technology for manufacturing applications in everything from aerospace, to education, to medicine. For automobiles, it helps develop significantly lighter-weight parts which can help improve fuel efficiency. A 3D-printed spoiler, for instance, could weigh less than half of its metal-cast equivalent. Additionally, it is also more cost effective for low volume production.

For 3D printing to work, specifications for the component are transferred from the computer-aided design program to the printer’s computer, which analyzes the design. The device prints one layer of material at a time, gradually stacking the layers into a finished 3D object. Using traditional methods, an engineer would create a computer model and wait for months for prototype tooling to be produced. With 3D printing, the same can be done in a matter of days at a significantly reduced cost.